About Us

Dongguan Jisheng Automation Equipment Technology Co., Ltd

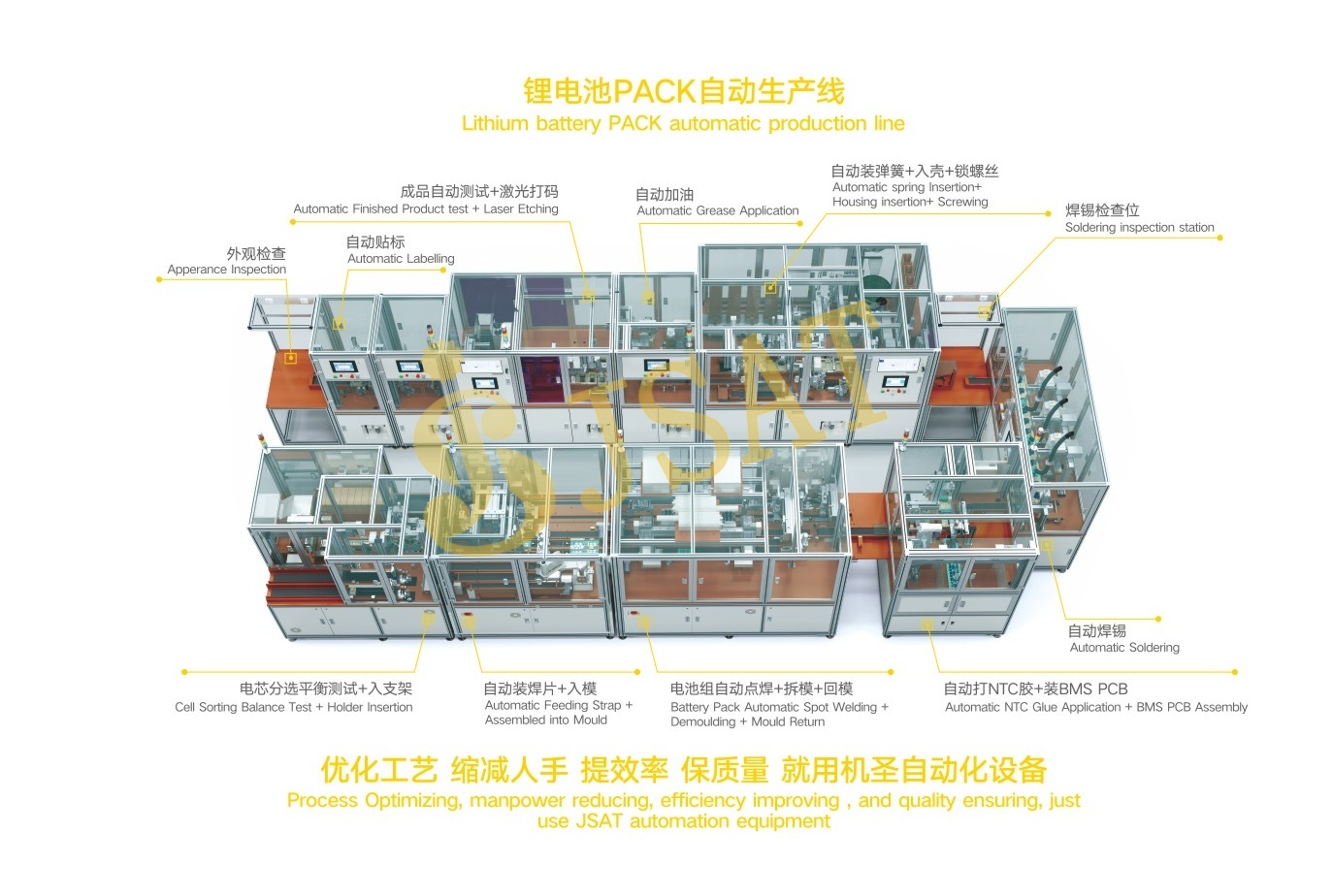

Dongguan Jisheng Automation Equipment Technology Co., Ltd., established in 2017, is a national high-tech enterprise and a specialized, refined, distinctive and innovative enterprise that specializes in the research and development, production, and sales of equipment technology for lithium battery (cylindrical, prismatic, pouch) PACK production lines. The company's production line equipment is mainly applied in the automated assembly and production of battery packs for power tools, garden tools, energy storage, household appliances, outdoor power supplies, two-wheel and three-wheel vehicles, and intelligent robots.

News

Gather real-time dynamics to understand the latest information of the machine.

Partners

Certificates

Six reasons to choose Jisheng

Technological Innovation

Having over ten years of research and development experience

- Jisheng has been deeply involved in the industry for more than ten years, with a research and development team of over 30 people, including 18 mechanical engineers, 8 electrical engineers, 6 software engineers (including vision, testing, robotics, MES), and 2 product process engineers. At present, 119 patents have been obtained, covering 32 invention patents, 80 utility model patents, and 7 computer copyright patents.

Optimize the process

Reduce costs, increase efficiency, and ensure quality for customers

-

We have provided a complete line solution for the world's most valuable lithium electric tool brand. By optimizing the product process structure, we can achieve a 90% reduction in the entire line, from the original 33 workers to 3 workers. This has increased the production capacity of our customers by 190%, from 200 sets of products per hour to 380 sets per hour. At the same time, we have saved a lot of material costs, bringing significant cost advantages and efficiency improvements to our customers.

Timely delivery

All production lines are delivered on time and can be produced within 7 days of arrival

-

The company has independent processing centers equipped with over 50 devices, which can quickly respond to market demand and complete deliveries on time, with high quality and quantity. All equipment must pass the debugging and inspection before leaving the factory. After receiving the equipment, customers only need to power on and ventilate it for fine-tuning, and it can be quickly put into use to ensure timely delivery of the project and reduce customer waiting time.

Quality control

Strictly monitor every detail

-

Equipped with an 8S international advanced management production workshop, it has formed 159 production inspection procedures in the industry. Every detail of every process must undergo strict inspection and testing to ensure compliance with standards.

Service system

Comprehensive and rapid response service

-

A rapid response customer service team, including pre-sales service, in sales service, after-sales service, customer training and other professional teams, providing 7 * 24-hour comprehensive rapid response services.

Free training

Free operation training for professional personnel

-

Para garantizar que los clientes puedan usar el equipo de manera eficiente y segura, ofrecemos servicios profesionales de capacitación puerta a puerta para ingenieros post - venta para resolver los problemas del proyecto a tiempo a través del soporte in situ o la asistencia de software remoto.

Contact Us

Mobile: +86-18681129808(mr. luo)

Tel: +86-769-85872681 | +86-769-85872682

Fax: +86-769-85872680

Email: xingyezdh@163.com | lcb@jsat.cn

Add.: No. 8, Chiling Industrial Third Ring Road, Houjie Town, Dongguan City, Guangdong Province