|

|

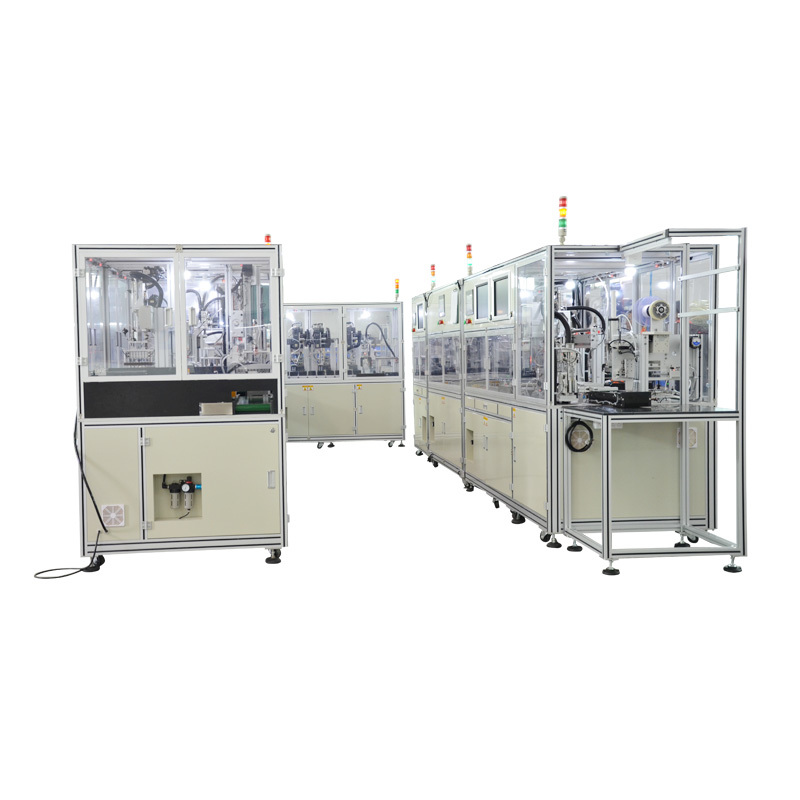

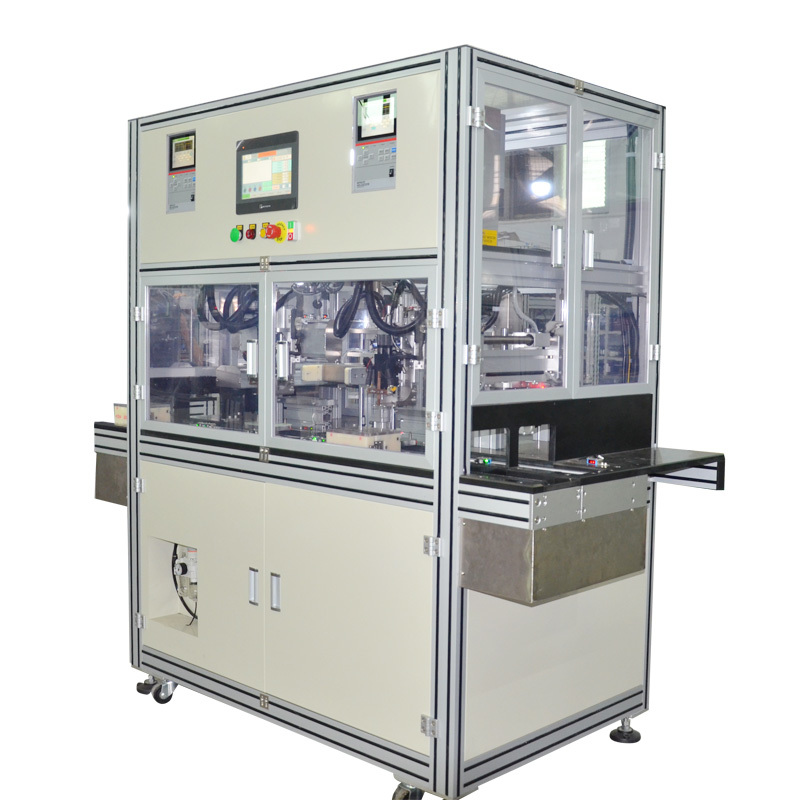

| Lithium battery automatic screw machine and test machine |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Automatic feeding conditions |

|

| Screw Length> Nut Diameter 1.3mm |

|

| Screwdriver specifications |

|

| No carbon brush electric batch or wind batch, torque 2-12KGF.CM |

|

|

|

| 30 pieces/min (calculated by M3 * 10 screws), |

|

| Electric wind or wind batch torque detection |

|

|

| Multi-feed screw detection |

|

| There is (more or less screw machine will not start) |

|

|

|

| There is (more or less screw machine will not start) |

|

|

|

| There is (sound and light alarm for defective products, and the touch screen has records) |

|

|

|

| There is (sound and light alarm for defective products, and the touch screen has records) |

|

| Inspection for screw leakage |

|

| There is (sound and light alarm for defective products, and the touch screen has records) |

|

| Battery terminal tightness detection |

|

| There is (set the upper and lower limits, sound and light alarm for defective products, and the touch screen has records) |

|

| Battery internal resistance detection |

|

| There is (set the upper and lower limits, sound and light alarm for defective products, and the touch screen has records) |

|

| Battery NTC and ID resistance detection |

|

| There is (set the upper and lower limits, sound and light alarm for defective products, and the touch screen has records) |

|

|

|

|

| Automatic barcode scanning |

|

|

| Product removal inspection |

|

|

|

|

Customized according to customer requirements |

|

|

|

| |

|