Automated labeling machine: A new solution for six-axis robot vision alignment in automated labeling

Release time:

2025-07-29

In the production process of power tool battery packs, the labeling step, as a crucial stage for presenting product information and brand identification, has a significant impact on product quality and production efficiency. The traditional labeling methods have gradually revealed their inadequacies when confronted with the increasing production demands and strict labeling standards.

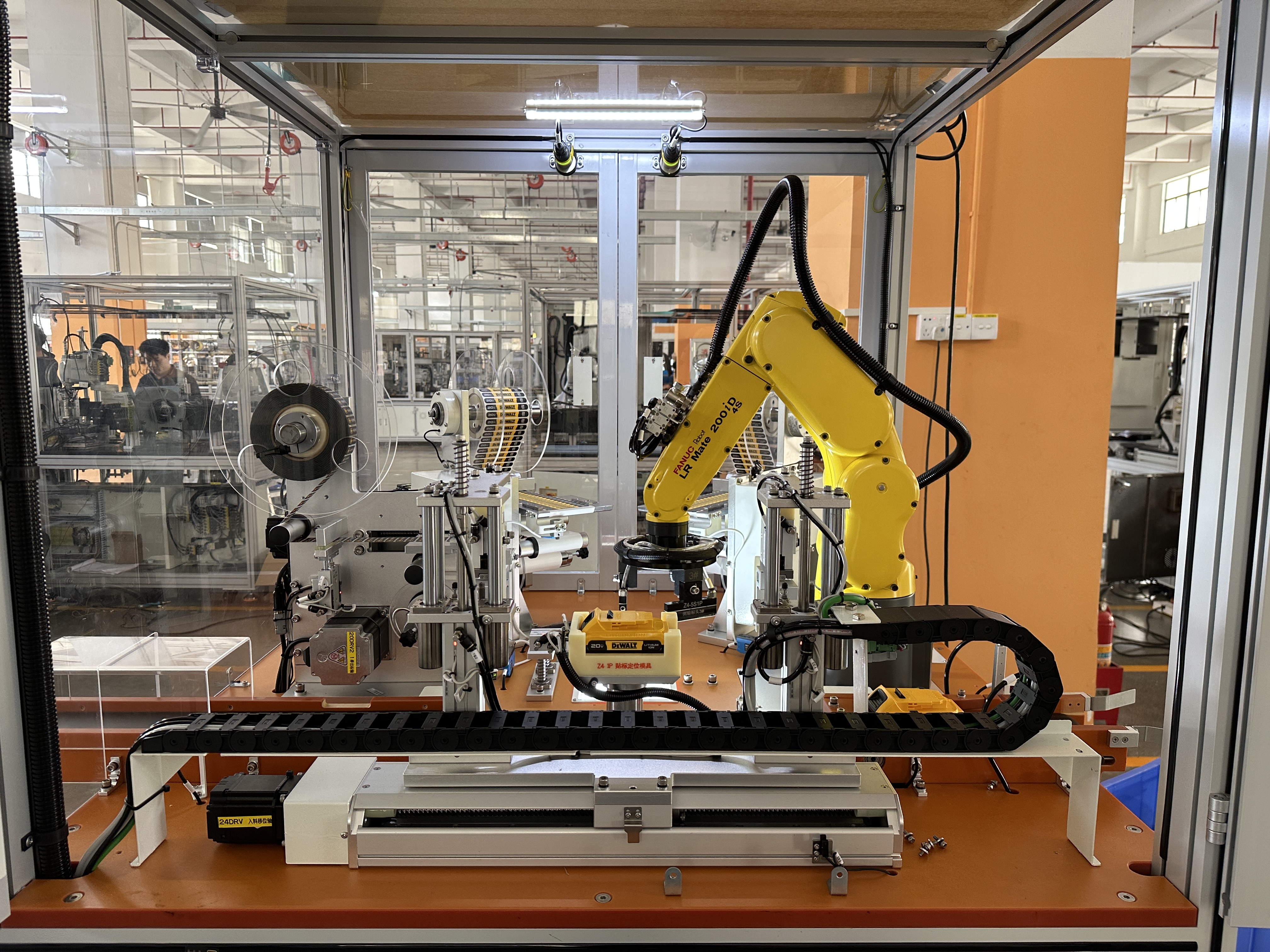

This non-standard customized automatic labeling machine, independently developed by Ji Sheng, provides customers with a revolutionary solution for the production of electric tool battery packs by applying six-axis robot configuration and visual alignment technology, thus opening a new chapter of high-efficiency and precise labeling.

I. Limitations of Traditional Labeling Methods

In the past, the labeling of electric tool battery packs mostly relied on manual operation or relatively basic semi-automatic labeling equipment. Although manual labeling offers a certain degree of flexibility, it has obvious drawbacks. On the one hand, manual operation is limited by human physiological functions, making it difficult to significantly increase the labeling speed. Under the demand for large-scale production, labor costs increase sharply, and prolonged repetitive work can cause fatigue among workers, leading to a decrease in labeling efficiency. On the other hand, the accuracy of manual labeling depends entirely on individual experience and current state. There are differences in labeling positions, flatness, etc., among different operators, making it difficult to ensure consistency in product labeling. Issues such as skewed labels and air bubbles occur frequently, seriously affecting the appearance quality of the products and the brand image.

Although semi-automatic labeling equipment has improved the labeling speed to a certain extent, it lacks flexibility when dealing with the diverse sizes, shapes, and complex labeling position requirements of battery packs. Adjusting the equipment is time-consuming and labor-intensive, and its positioning accuracy is affected by factors such as mechanical structure wear and vibration. After long-term operation, the labeling accuracy is difficult to maintain stably, failing to meet the demands of electric tool battery pack manufacturers for high-quality and high-efficiency production.

II. Technical Composition of the Six-Axis Robot Automatic Labeling Machine

(1) Core Six-Axis Robot

The six-axis robot is the main executor of the labeling machine. Its six joint axes are designed to give the robot highly flexible movement capabilities, allowing it to freely extend, rotate, and position in three-dimensional space like a human arm. Each joint axis is driven by high-precision servo motors, which have strong torque output and precise position control capabilities. Through advanced motion control algorithms, the robot can quickly plan and execute complex labeling trajectories, from picking up the label, transferring it, to accurately attaching it to the designated position on the battery pack. The entire process is smooth and precise. For example, when faced with irregularly shaped battery packs, the six-axis robot can flexibly adjust its posture to ensure that the label conforms to the surface curvature of the battery pack, achieving perfect labeling.

(2) Precise Visual Alignment System

The visual alignment system acts as the "eyes" of the labeling machine, providing real-time and precise position information for the labeling process. This system mainly consists of high-resolution industrial cameras, light sources, and image processing software. The industrial cameras are installed on the robot arm or fixed in appropriate positions, capable of clearly capturing images of the area to be labeled on the battery pack and the label. The light sources optimize the lighting conditions to enhance the contrast of image features, making it easier for the camera to obtain more accurate image information.

The image processing software uses advanced image recognition algorithms to quickly analyze and process the images captured by the camera. It can precisely identify the contour of the battery pack, locate feature points, and determine the position and angle of the label. It calculates the relative position deviation between the label and the battery pack and feeds this information back to the control system of the six-axis robot in real time. Based on this feedback, the robot quickly adjusts its movement trajectory to achieve precise alignment between the label and the battery pack, ensuring that the labeling position error is controlled within an extremely small range.

III. Workflow of the Six-Axis Robot Automatic Labeling Machine

(1) Battery Pack Feeding and Positioning

Electric tool battery packs are precisely conveyed to the working area of the labeling machine through an automated conveyor line. On the conveyor line, there is a dedicated positioning fixture that uses a combination of mechanical positioning and sensor detection to ensure that each battery pack reaches the labeling position with a consistent posture and precise location, laying the foundation for subsequent visual alignment and labeling operations. For example, photoelectric sensors detect the edge position of the battery pack, triggering the positioning cylinder to act, precisely fixing the battery pack in the preset position, ensuring that the battery pack images captured by the camera are consistent.

(2) Label Picking and Visual Inspection

At the label supply device, rolls of labels are smoothly conveyed to the label picking position through the unwinding mechanism and tension control system. The six-axis robot quickly moves to the label picking point based on the initial position information fed back by the vision system, and precisely picks up the label using a vacuum suction cup or a dedicated picking device installed on the robot's end effector. After picking up the label, the robot moves to the visual inspection area, where the camera re-takes a picture of the picked label to confirm whether it has been picked up correctly and whether there are any wrinkles or damages. If defects are found in the label, the system will automatically issue an alarm and control the robot to discard the label and pick up a new one to ensure the quality of the label used for labeling.

(3) Visual Alignment and Labeling Execution

After completing the label picking and inspection, the six-axis robot carries the label to the top of the battery pack. At this time, the vision system is activated again, and the industrial camera simultaneously captures images of the battery pack's labeling area and the label. The image processing software quickly calculates the positional deviation between the two. The robot control system adjusts the motion parameters of each joint axis of the robot in real time based on the calculation results, precisely controlling the posture and position of the robot arm to achieve precise alignment between the label and the battery pack's labeling area. When the positional deviation meets the labeling accuracy requirements, the robot slowly lowers its arm, smoothly attaches the label to the surface of the battery pack, and uses a rolling device to moderately roll the label to ensure it adheres tightly to the battery pack surface without air bubbles or wrinkles.

(4) Labeling Quality Inspection and Discharge

After the label is attached, the vision system conducts a final inspection of the labeling quality. The camera takes pictures of the labeled battery pack, and the software analyzes whether the label position is accurate, whether the attachment is flat, and whether there are any missed labels or lifted edges. The inspection results are fed back to the control system in real time. If the labeling quality is qualified, the battery pack is conveyed to the next production stage through the conveyor line; if there are labeling defects, the system marks the defective battery packs and diverts them to the repair area for manual or specialized equipment processing.

IV. Notable Advantages of the Six-Axis Robot Automatic Labeling Machine

(1) Rapid and Efficient Labeling Speed

The six-axis robot, with its high-speed motion performance and precise motion control, can complete a series of actions such as label picking, transfer, and attachment in a short time. Compared with manual labeling and traditional semi-automatic labeling equipment, its labeling speed has been significantly improved. In large-scale production of electric tool battery packs, it can significantly shorten the production cycle, increase production efficiency, and meet the growing production capacity demands of enterprises. For example, on a certain electric tool battery pack production line, after adopting the six-axis robot automatic labeling machine, the labeling efficiency increased several times, with the number of labels per hour rising from several hundred to over a thousand, effectively alleviating the production bottleneck problem.

(2) Unparalleled Labeling Accuracy

The application of visual alignment technology has achieved an unprecedented level of labeling accuracy. Through real-time visual detection and precise position calculation of the battery pack and label, the six-axis robot can accurately attach the label to the designated position on the battery pack, with position errors controlled within an extremely small range, typically reaching ±0.1mm or even higher precision. This ensures the consistency and accuracy of the labeling position for each battery pack, greatly enhancing the product's appearance quality and brand image. In the production of high-end electric tool battery packs with extremely high labeling accuracy requirements, the high-precision advantage of the six-axis robot automatic labeling machine is particularly prominent, effectively reducing the product defect rate caused by labeling errors.

(3) Strong Flexibility and Adaptability

The multi-joint structure and programmable characteristics of the six-axis robot enable it to easily adapt to the labeling needs of electric tool battery packs of different sizes and shapes. With simple programming adjustments, the robot can quickly switch labeling modes to meet the requirements of diverse product production. At the same time, the visual alignment system can real-time identify changes in the battery pack's features and automatically adjust the labeling parameters to ensure precise labeling under different working conditions. For instance, when the battery pack size changes, the visual system can quickly recognize the new contour and positioning feature points, and the robot adjusts the labeling trajectory based on the new position information, without the need for complex mechanical adjustments to the equipment, greatly enhancing the equipment's versatility and production flexibility.

(4) Stable and reliable operation performance

The overall structure of the labeling machine is compact and reasonable. High-quality materials and advanced manufacturing processes are selected for key components to ensure stable and reliable performance during long-term and high-intensity operation. The six-axis robot has undergone strict quality inspection and optimized design, featuring high rigidity and low vibration, capable of withstanding frequent start-stop and high-speed movement impacts. The vision alignment system uses industrial-grade hardware equipment and mature image processing algorithms, with strong anti-interference ability. It can operate stably in complex production environments, ensuring the continuity and stability of the labeling process and effectively reducing equipment failure rates and maintenance costs.

V. Summary and Outlook

The six-axis robot automatic labeling machine, with its numerous advantages such as high speed and efficiency, precise labeling, flexible adaptability, and stable reliability, has become the ideal solution for the labeling process in the production of power tool battery packs. It not only effectively addresses the limitations of traditional labeling methods, enhancing production efficiency and product quality, but also brings significant economic benefits and market competitiveness to enterprises. With the mission of reducing costs, increasing efficiency, and ensuring quality for customers, the six-axis robot automatic labeling machine is expected to achieve even higher labeling speeds and precision in the future, further expanding its application fields and scope. At the same time, the equipment will become more intelligent and user-friendly, better integrating with the overall production systems of enterprises, and injecting new vitality and impetus into the intelligent upgrade and sustainable development of the power tool battery pack production industry.

Recommended News