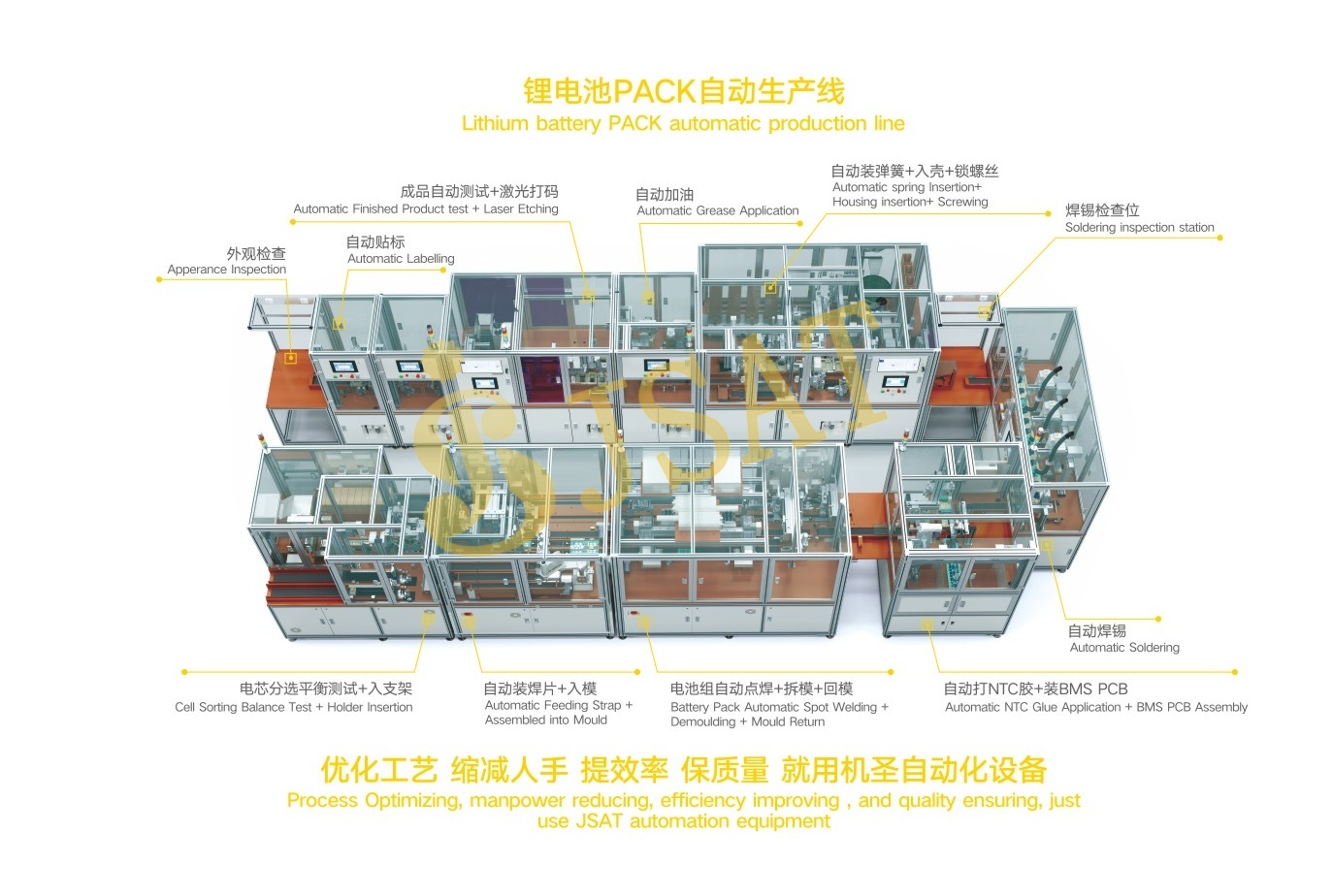

Automated production line for power tool battery packs

Release time:

2025-08-30

In the modern industrial manufacturing field, power tools, with their convenience and efficiency, are widely used in many scenarios such as construction, home decoration, and mechanical maintenance. As for the battery PACK, which is the "heart" of power tools, the degree of automation in its production process directly affects product quality, production efficiency and the competitiveness of enterprises. This article will delve into the key workstations of the automated production line for power tool battery packs

Analysis of Key Workstations in the Automated Production Line for Electric Tool Battery Packs

(1) Battery cell sorting

As the core unit of a battery PACK, the performance consistency of the battery cell has a profound impact on the stability and lifespan of the entire battery pack. At the battery cell sorting station, high-precision detection equipment is used to test key parameters such as the capacity, internal resistance and voltage of the battery cells one by one. Based on the test data, the battery cells are precisely sorted into different grades according to the differences in performance parameters. For instance, cells with similar capacities and consistent internal resistances are grouped into the same batch to ensure that the performance matching degree of each cell in the subsequent assembled battery PACK is high, reducing local overcharging and overdischarging caused by cell differences, thereby enhancing the overall performance and service life of the battery PACK.

(2) Insert the battery cell into the bracket

The sorted battery cells need to be precisely installed into specific brackets to build the basic structure of the battery module. Automated equipment, with the aid of advanced mechanical arms and visual recognition systems, can quickly grasp battery cells and insert them one by one with extremely high precision according to the preset holes of the brackets. The movements of the mechanical arm have been precisely programmed to ensure placement accuracy while strictly controlling the grasping force to avoid physical damage to the battery cells. The visual recognition system monitors the positional relationship between the battery cells and the bracket in real time. Once a deviation occurs, it immediately feeds back and adjusts the movement of the mechanical arm to ensure the efficient and stable operation of the battery cell insertion into the bracket.

(3) Automatically install and weld the sheet into the mold

Solder sheets play a crucial role in connecting battery cells and transmitting current in battery modules. The automated equipment of this work station can automatically select the appropriate specification of solder sheets according to the design requirements of the battery PACK and precisely place them at the connection points of the positive and negative electrodes of the battery cells. Subsequently, the equipment moves the module with solder sheets and battery cells as a whole into the mold to prepare for the subsequent welding process. During this process, the automated equipment strictly controls parameters such as the size, material, and placement position of the welding sheets to ensure the firmness and conductivity of the welding, and to guarantee the stable current transmission of the battery PACK during charging and discharging.

(4) Spot welding of battery packs

Spot welding is an important process that firmly connects battery cells to solder sheets to form a stable circuit connection. The automated spot welding equipment adopts advanced resistance spot welding technology. By precisely controlling the current size, power-on time and electrode pressure, it achieves high-quality welding results. During the welding process, the equipment monitors parameters such as welding current and voltage in real time. Once any abnormality is detected, the welding is immediately stopped and an alarm is issued. Meanwhile, the spot welding equipment has high-speed welding capabilities and can complete the welding of a large number of battery cells and solder sheets in a short time, greatly enhancing production efficiency and meeting the demands of large-scale production. For instance, some advanced spot welding equipment can complete multiple spot welding operations per second, and the welding quality is stable and reliable.

(5) Automatically apply NPC glue

NPC glue plays a role in fixing battery cells, enhancing structural stability, and improving shock resistance in battery packs. The automatic gluing equipment is equipped with a high-precision gluing volume control system and a mechanical arm, which can precisely control the gluing position and volume according to the structural design of the battery PACK. The robotic arm evenly applies NPC glue to the parts that need to be fixed, such as the battery cells and brackets, modules and casings, along the preset path. The glue quantity control system ensures that the amount of glue applied each time is consistent, avoiding any impact on product quality due to excessive or insufficient glue. After the gluing is completed, the adhesive undergoes a specific curing process (such as heating curing, natural curing, etc.) to closely bond the internal structure of the battery PACK and enhance overall reliability.

(6) Install the BMS

The BMS (Battery Management System) is like the "intelligent brain" of the battery PACK, responsible for monitoring parameters such as voltage, current, and temperature of the battery, and realizing functions such as charge and discharge management, overcharge and overdischarge protection, and balance management of the battery. At the BMS installation station, the automated equipment accurately installs the BMS modules that have passed the pre-test to the corresponding positions of the battery PACK and completes the electrical connection. During the installation process, the equipment automatically identifies and matches the model and version of the BMS to ensure its compatibility with the battery PACK. Meanwhile, through the automated testing system, the communication function between the BMS and the battery PACK, as well as the accuracy of data collection, are preliminarily tested to ensure the normal operation of the BMS and provide a guarantee for the safe and stable operation of the battery PACK.

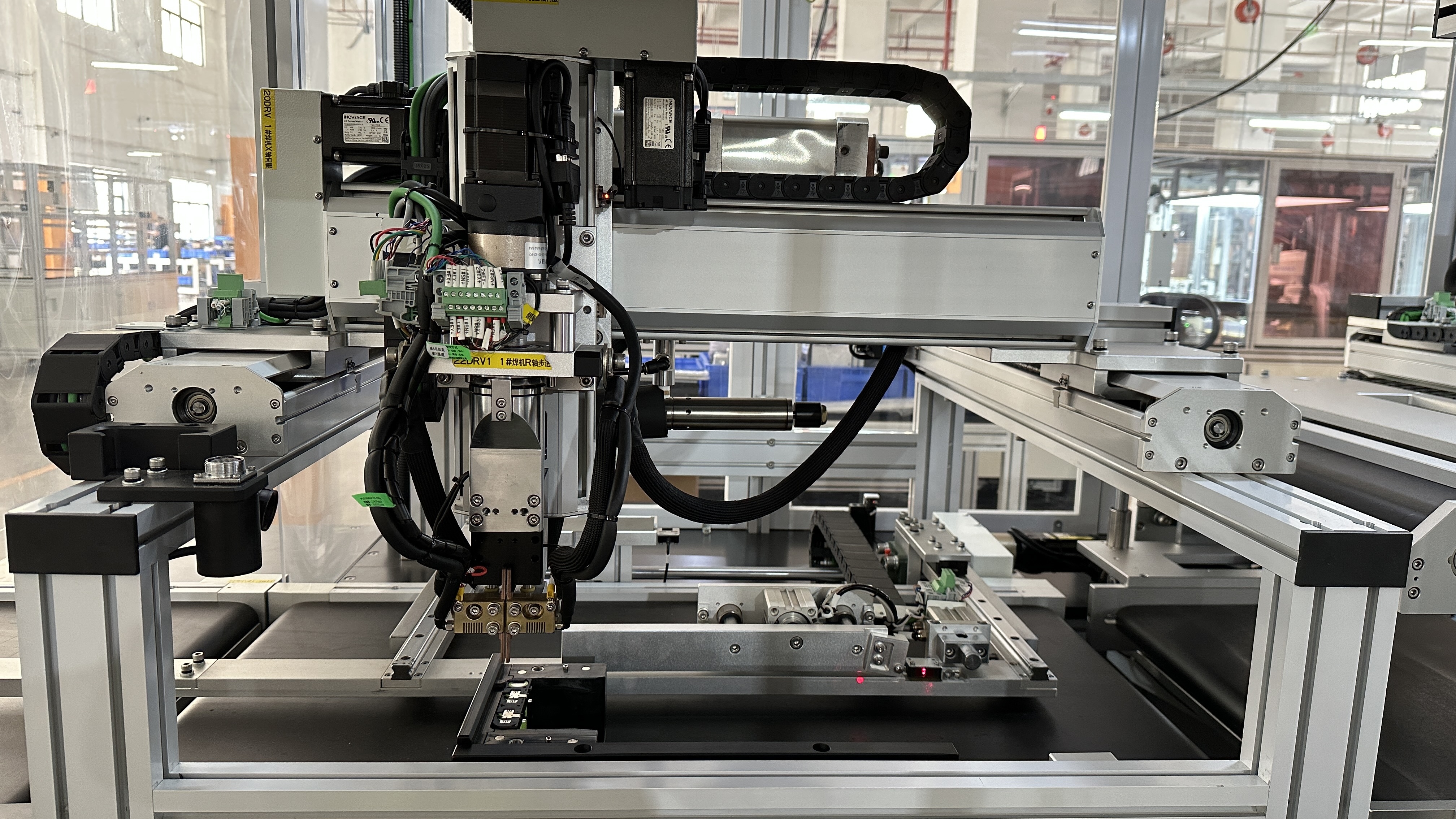

(7) Automatic soldering

Some of the connection wires between the BMS and the battery cells will be processed by automatic soldering. The automatic soldering equipment is equipped with a precise temperature control system and soldering heads, which can precisely control the soldering temperature and soldering time. During the welding process, the equipment automatically sends an appropriate amount of solder wire to the welding area. Through the heating of the welding head, the solder wire melts, thus achieving a reliable electrical connection. The temperature control system ensures that the welding temperature is always within an appropriate range, which not only guarantees that the solder melts fully but also prevents damage to components due to excessively high temperatures. Compared with traditional manual soldering, the automatic soldering process has the advantages of stable soldering quality, good consistency and high production efficiency.

(8) Comprehensive testing of finished products

The battery PACK that has been assembled and welded must undergo comprehensive and strict integrated testing to ensure that all its performance indicators meet the design requirements and industry standards. Comprehensive testing equipment includes a variety of specialized devices such as charge and discharge testing systems, internal resistance testing instruments, insulation performance testing devices, and temperature cycling test chambers. During the charge and discharge test phase, the charging and discharging conditions of the battery PACK in actual use are simulated to detect parameters such as its capacity, charge and discharge efficiency, and cycle life. Internal resistance testing is used to evaluate the resistance size of the internal connections of the battery PACK and determine whether the connections are good. The insulation performance test ensures that the battery PACK will not experience leakage during use, guaranteeing the safety of users. The temperature cycling test simulates the working state of the battery PACK under different environmental temperatures to detect its performance stability under temperature changes. Only battery packs that pass all test items can be judged as qualified products and proceed to the next process.

(9) Automatic labeling and visual inspection

Before the finished battery packs leave the factory, the automatic labeling equipment accurately adheres the labels containing key information such as product model, specification parameters, production date, production batch, and QR code to the designated positions on the surface of the battery PACK shell based on the product information. During the label application process, the equipment conducts real-time detection of the label's position and flatness to ensure that the label is firmly adhered, clear and easy to read. During the visual inspection stage, with the aid of a visual inspection system, a comprehensive check is conducted on the integrity of the battery PACK's casing, surface flatness, the appearance of the welding areas, and the clarity of the markings. Once any scratches or deformations on the shell, false or missed welds at the welding points, or blurred markings are detected, the system will immediately issue an alarm and remove the defective products to ensure that the appearance quality of the products leaving the factory meets the standards and enhance the brand image.

The automated production line for power tool battery packs has achieved high efficiency, accuracy and stability in the production process through meticulous control of each key workstation. Against the backdrop of the continuous growth in global demand for power tools, it provides strong support for enterprises to enhance their competitiveness and expand their market share. In the future, with the continuous innovation and upgrading of technology, the automated production line for power tool battery packs will develop in a more intelligent and flexible direction, injecting a continuous stream of impetus into the prosperous development of the power tool industry.

Recommended News