Lithium battery automatic spot welding equipment: The core of precision manufacturing in the new energy industry

Release time:

2025-08-02

Under the global backdrop of actively promoting sustainable energy development, lithium batteries, as key energy storage components in the new energy field, have a wide range of applications, from electric vehicles to portable electronic devices. As the core equipment in the lithium battery production process, the automatic spot welding equipment for lithium batteries plays a decisive role in the performance, safety and production efficiency of the batteries.

This article introduces the application of the American HF2 welding machine selected for the large-pack battery dual-station automatic spot welding equipment customized by Jisheng Automation for customers, as well as the significant benefits it brings.

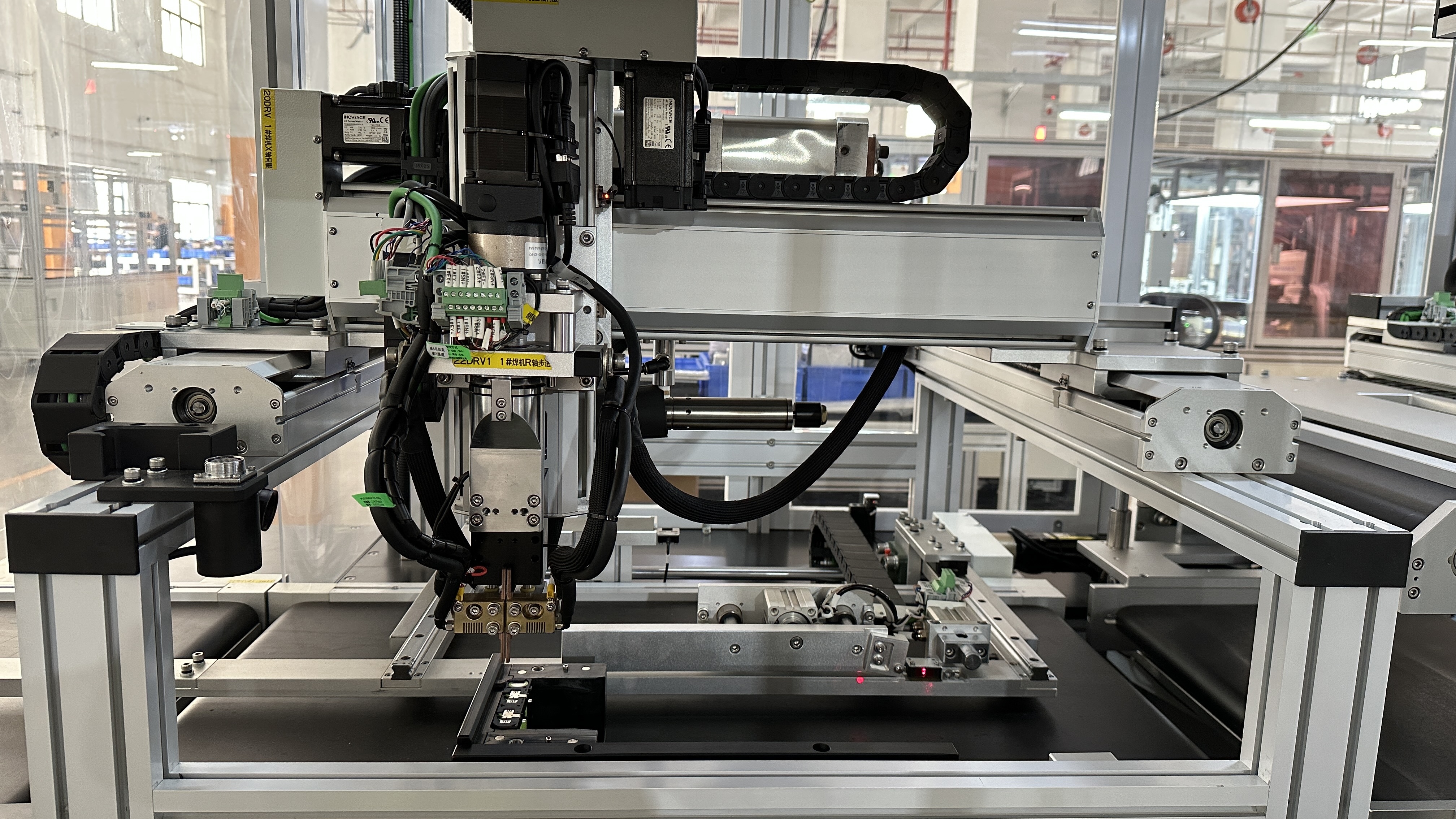

Real photos taken in the Jisheng workshop

I. Working Principle of Lithium Battery Spot Welding Equipment

The automatic spot welding equipment for lithium batteries mainly operates based on the principle of resistance welding. Resistance welding is a method in which the workpieces are assembled, pressure is applied through electrodes, and the resistance heat generated by the current passing through the contact surface and adjacent areas of the joint is used for welding. During the spot welding process, two electrode heads tightly press the components to be welded (such as nickel sheets and the electrode sheets or cells of lithium batteries) together, and a powerful current instantly passes through the contact point.

This process is highly time-sensitive and usually only takes milliseconds to complete the welding of a single solder joint. The equipment ADAPTS to welding materials of different thicknesses and materials as well as various complex welding requirements by precisely adjusting parameters such as current intensity, welding time, electrode pressure, and electrode shape and size.

For instance, when welding lithium battery electrodes, the electrodes are usually thin and highly sensitive to heat input. Therefore, it is necessary to precisely control the current and welding time to prevent overheating from causing damage to the electrodes or a decline in battery performance. Meanwhile, for different types of lithium batteries, such as cylindrical 18650 cells, square cells or pouch cells, the welding process parameters also vary. The automatic spot welding equipment can quickly switch and adjust the parameters according to the preset program to ensure the stability of the welding quality.

Spot welding head system

II. Components of Lithium Battery Spot Welding Machines

(1) Spot welding head system

The spot welding head is the core actuating component of the spot welding machine and directly acts on the welding area. It is usually composed of parts such as electrodes and electrode fixtures. The electrode is the part that comes into direct contact with the welding material. Its material is generally copper alloy with good electrical and thermal conductivity to ensure efficient current transmission and heat dissipation. The vertical downward pressure spot welding method with the welding needle is adopted, and the downward pressure can be adjusted to ensure stable and reliable welding.

(2) Control System

The control system is the "brain" of the automatic spot welding equipment for lithium batteries, responsible for coordinating and controlling the entire welding process. It is mainly composed of a microcomputer, a programmable logic controller (PLC), and various sensors. The control system precisely controls the power supply system to output the appropriate current based on various welding parameters input by the operator through the human-machine interface of the equipment, and controls the transmission system to drive the spot welding head for accurate positioning and welding operations. Various sensors monitor various physical quantities during the welding process in real time, such as current sensors to monitor the magnitude of the welding current, pressure sensors to monitor the electrode pressure, and temperature sensors to monitor the temperature of the weld joint, etc. Once the sensor detects that the actual parameters deviate from the preset values, the control system will immediately make adjustments to ensure the stability of the welding process and the reliability of the welding quality.

(3) Power Supply System

The power supply system provides the powerful electrical energy required for the spot welding process. In the equipment configuration, to select the American HF2 welding machine as the power supply,Its high-frequency inverter technology can convert ordinary alternating current into 2kHz high-frequency alternating current, allowing heat to be highly concentrated in the welding area. When welding the square battery cell tabs and connecting plates, it effectively avoids the damage to the interior of the battery cell caused by heat diffusion. Meanwhile, its high-speed digital adaptive feedback system can adjust the welding parameters deviating from the preset values within 250 microseconds, ensuring that the quality of each weld point is highly consistent. The welding speed can reach 1 second per weld spot, and it will not get hot even after long-term operation.

In the production of small lithium batteries for portable electronic devices, many customers mainly deal with 18650 cylindrical cells. These cells are small in size, have a precise structure, and have strict requirements for welding accuracy. The selectable welding energy limit function of the HF2 welding machine we selected for our customers has played a crucial role in production. It can precisely set the upper limit of welding energy based on the characteristics of 18650 battery cells, ensuring the connection strength of the weld points while completely avoiding thermal damage to the battery cells caused by excessive energy. Moreover, the lifespan of its electrodes is more than five times longer than that of traditional spot welding equipment, significantly reducing the downtime caused by electrode replacement and enhancing the continuous production capacity of customers. After the customer started using the equipment equipped with the HF2 welding machine, the quality stability of the small lithium battery products was significantly improved, and the production efficiency increased by more than 30%, better meeting the market demand for high-quality small lithium batteries.

HF2 welding power supply

(4) Transmission System

The transmission system is responsible for controlling the movement of the spot welding head to achieve precise control of the welding position. It is generally composed of a motor, a transmission device (such as lead screws, guide rails, belts, etc.) and a motion controller. The motor, as the power source, provides precise driving force according to the instructions of the control system, driving the spot welding head to move in three-dimensional space. The transmission device converts the rotational motion of the motor into the linear motion of the spot welding head and ensures the accuracy and smoothness of the motion.

III. Advantages of Automatic Spot Welding Equipment for Lithium Batteries

(1) High precision and high stability

The automatic spot welding equipment for lithium batteries can achieve extremely high welding accuracy through an advanced control system and precise mechanical structure. For instance, the welding accuracy can reach ±0.01mm, and the repeatability error is less than 0.5%. This is crucial for the production of lithium batteries, as the electrode sheets and connection sheets of lithium batteries are usually very thin, and the position and quality of the solder joints directly affect the performance and safety of the battery. High-precision welding can ensure uniform and firm weld points, reduce the occurrence of defects such as false welding and false welding, and thereby improve the consistency and reliability of battery packs. Meanwhile, the stability of the equipment has been greatly enhanced. During long-term continuous production, it can maintain stable welding parameters and quality, reduce product quality problems caused by equipment fluctuations, and improve production efficiency and product qualification rate.

(2) High efficiency and energy conservation

The automatic spot welding equipment adopts advanced power supply technology and optimized welding processes, achieving remarkable energy-saving effects. For instance, the power factor of capacitive energy storage spot welding machines can reach over 0.9, and compared with traditional welding equipment, the instantaneous power consumption is reduced by approximately 40%. While enhancing energy utilization efficiency, the welding speed of the equipment has also been significantly increased. Efficient welding speed not only meets the demands of large-scale production, but also shortens the production cycle, reduces production costs and enhances the market competitiveness of enterprises.

(3) Intelligence and Automation

With the continuous advancement of technology, automatic spot welding equipment for lithium batteries is becoming increasingly intelligent and automated. The equipment is equipped with an intelligent control system, which can automatically set, store and call up welding parameters. The operator only needs to input the product model or welding task number through the human-machine interface, and the equipment can automatically load the corresponding welding parameters, greatly improving the convenience of operation and production efficiency. Meanwhile, the equipment is also equipped with automatic detection and fault diagnosis functions, capable of real-time monitoring of various parameters and equipment status during the welding process. Once any abnormal situation is detected, it can immediately stop the welding and issue an alarm signal to prompt the operator to handle it.

In addition, on some automated production lines, automatic spot welding equipment can also be seamlessly integrated with other automated equipment (such as robots, conveyor belts, etc.) to achieve fully automated operation of the entire production process, reduce manual intervention, and improve the consistency and stability of production.

Battery module

IV. Summary

As a core device in the lithium battery production process, the automatic spot welding equipment for lithium batteries plays a crucial role in promoting the development of the lithium battery industry with its significant advantages such as the precise welding principle based on resistance heat, the composition structure of multi-system collaborative work, as well as high precision, high stability, high efficiency and energy conservation, intelligence and automation, and wide applicability. The automatic spot welding equipment for lithium batteries produced by our company is equipped with the American HF2 welding machine, which fully demonstrates these advantages, bringing significant benefits to the lithium battery production of our customers. It not only improves product quality and production efficiency but also enhances their competitiveness in the market.

Previous Page

Recommended News